The global gelatin market continues to grow and companies are looking for efficient production processes. In particular, improvements in the drying stage can lead to significant improvements. Currently, 50-60% of global gelatin is dried using longinet gelatin dryers.

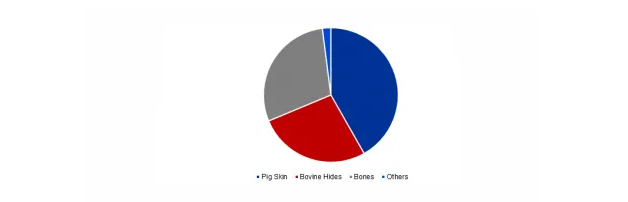

Gelatin is derived from collagen, a human protein. The three main sources of gelatin are cattle bones, pig skins and cow hides. Pork gelatin is a hydrolyzed product of pork collagen. Bovine gelatin comes from cattle. Currently, pig skin is the most widely used, followed by cow hides. However, due to cultural and religious objections to the use of bovine gelatin, especially porcine gelatin, fish by-products are also being used.

The rise of the gelatin market

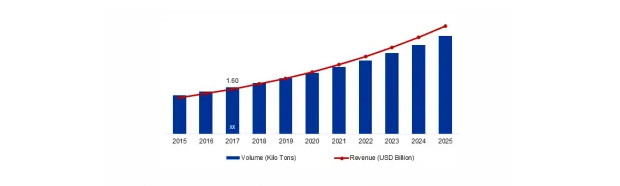

Gelatin has been used for centuries, but the global gelatin market has grown significantly in recent years. As people age and become more health conscious, the demand for functional and nutritious foods has grown. This, in turn, has boosted the production of food-grade gelatin, collagen peptides, and sub-proteins. After all, gelatin is not only high in protein and low in fat, but also has excellent stabilizing, binding, and emulsifying properties, allowing it to be used in a wide range of foods.

In addition, gelatin's wound healing, biodegradability, and high absorption properties have driven the demand for medical and pharmaceutical-grade gelatin. Its thickening and gelling properties make it attractive in the personal care market. As shown in the figure below, the growth momentum of food-grade, medical, and pharmaceutical-grade gelatin production continues unabated:

However, as the gelatin market grows, there are challenges to optimize the gelatin production process. Improvements in the drying stage, in particular, can bring impressive optimization results.

Gelatin Manufacturing Process

Pretreatment:

When the raw materials arrive at the processing plant, they are first washed to remove debris. Hair is removed from the hides and all materials are boiled and defatted.

Gelatin Hydrolysis

Next, the raw materials are hydrolyzed using an acid or alkali. Acid treatment is mainly used for pig skins and takes up to 2 days. The gelatin obtained in this way is called type A gelatin. For cow hides, alkali treatment is usually used. It takes several weeks to obtain type B gelatin.

Gelatin hydrolysis can also be performed using enzymes, which takes less time than alkaline gelatin hydrolysis. This method is also said to improve the yield and quality of gelatin.

Gelatin Extraction Process:

During the gelatin hydrolysis stage, protein molecules are dissolved in hot water to form a dilute gelatin solution. The gelatin extraction process involves boiling the raw materials in water or an acid solution four to five times. After each boil, the gelatin liquid is pumped out to extract a gelatin solution of about 4%.

Gelatin Filtration and Evaporation

The next step in the gelatin manufacturing process is gelatin filtration: the liquid is pressed through a filter to remove any bone, tissue or skin that may remain. The substance is then concentrated using an evaporator. Finally, it is sterilized.

Gelatin Drying

After filtration, concentration and sterilization, the liquid is dried until it contains about 88% gelatin and 12% water. The Fourdrinier drying process begins with cooling the gelatin in a physical cooler. The unit consists of a horizontal heat transfer cylinder equipped with a scraper, a high-pressure pump and an extruder gelling section.

The removable heat transfer tubes are made of carbon steel with a hard chrome plated interior. All other contact parts are made of stainless steel. After the gelatin has cooled, it is spread out in the form of noodles on a stainless steel conveyor belt. Next, the gelatin is conveyed to a Fourdrinier drying tunnel.

Fourdrinier drying tunnel

The gelatin dryer is essentially a conveyor belt dryer. By blowing drying air regularly over the surface of the gelatin noodles, a thin film is formed, which prevents the sol-gel from re-liquefying as the air temperature gradually rises. Alternatively, the drying air of the gelatin dryer passes in a cross-flow through the gelatin layer laid on a perforated plate system. The gelatin drying tunnel is divided into several zones, each of which is maintained at a different temperature. In the first zone, the supply air temperature is about 25°C; in the last zone, the air is heated to 60°C, thus preventing the gelatin from degrading. The design of the long net tunnel achieves air and water homogeneity through state-of-the-art hot water injection and high-tech aerodynamics.

Gelatin Grinding

After leaving the conveyor dryer, the gelatin emerges in mat form, which is then broken into pieces about 20 mm long, called granulated gelatin, and stored in large bags. Alternatively, the granulated gelatin is conveyed to a fine grinder to produce gelatin powder, which is then sieved, mixed and packaged.

The most common gelatin drying problems

Gelatin degradation and brittleness

On the one hand, gelatin can be easily degraded if dried at too high a temperature, resulting in quality loss; on the other hand, gelatin can become brittle if dried at too low a temperature, affecting its use in functional, nutraceutical products and other fields.

What is the optimal temperature? What humidity should be maintained to avoid gelatin degradation? The answer is not simple, as the type and concentration of gelatin as well as the ambient humidity and temperature can affect the drying process.

Therefore, smart equipment is essential. Advanced dehumidification systems can precisely control temperature and humidity and adapt to daily and seasonal changes. In addition, a good gelatin dryer can be configured to your specific site and product conditions.

Inefficient energy use

Another problem in the gelatin production process is its high energy consumption. All stages require a lot of energy, and the drying (and cooling) of gelatin is no exception.

Utilizing waste heat and cheap coolants

As early as 1975, engineers discovered ways to save energy by utilizing evaporator waste heat and extracting part of the gelatin dryer's air volume. In addition, advanced systems use relatively cheap coolants such as well water, river water and cooling tower water to help cool the gelatin. Dew point humidity can be as low as -7°. These measures significantly reduce operating costs.

Industrial Dehumidifiers

In addition to these technical improvements, dehumidification systems are based on the drying properties of hygroscopic liquid solutions. Low-energy dehumidifiers, the dehumidification effect depends directly on the concentration and temperature of the gelatin solution. Advanced overall energy consumption has been significantly reduced by 40%.

The issue of gelatin drying is related to food safety: Is gelatin safe to use?

The gelatin production process is absolutely safe. First, the high-efficiency sterilant is a non-toxic sterilizing solution that is sprayed into the air flow and can effectively remove and kill up to 97% of airborne bacteria, mold, fungi and specific viruses. In addition, it is not poisoned by hydrocarbons and is not affected by normal factory environments;

Second, advanced dehumidification systems also eliminate the problem of "wet" cooling coils, because moisture is a breeding ground for bacteria and mold. In long-term storage, this can significantly improve product quality. In short, finding the optimal temperature and humidity levels can achieve excellent gelatin quality at lower energy costs while maintaining food or pharmaceutical grade quality.

Post time: Jun-03-2025